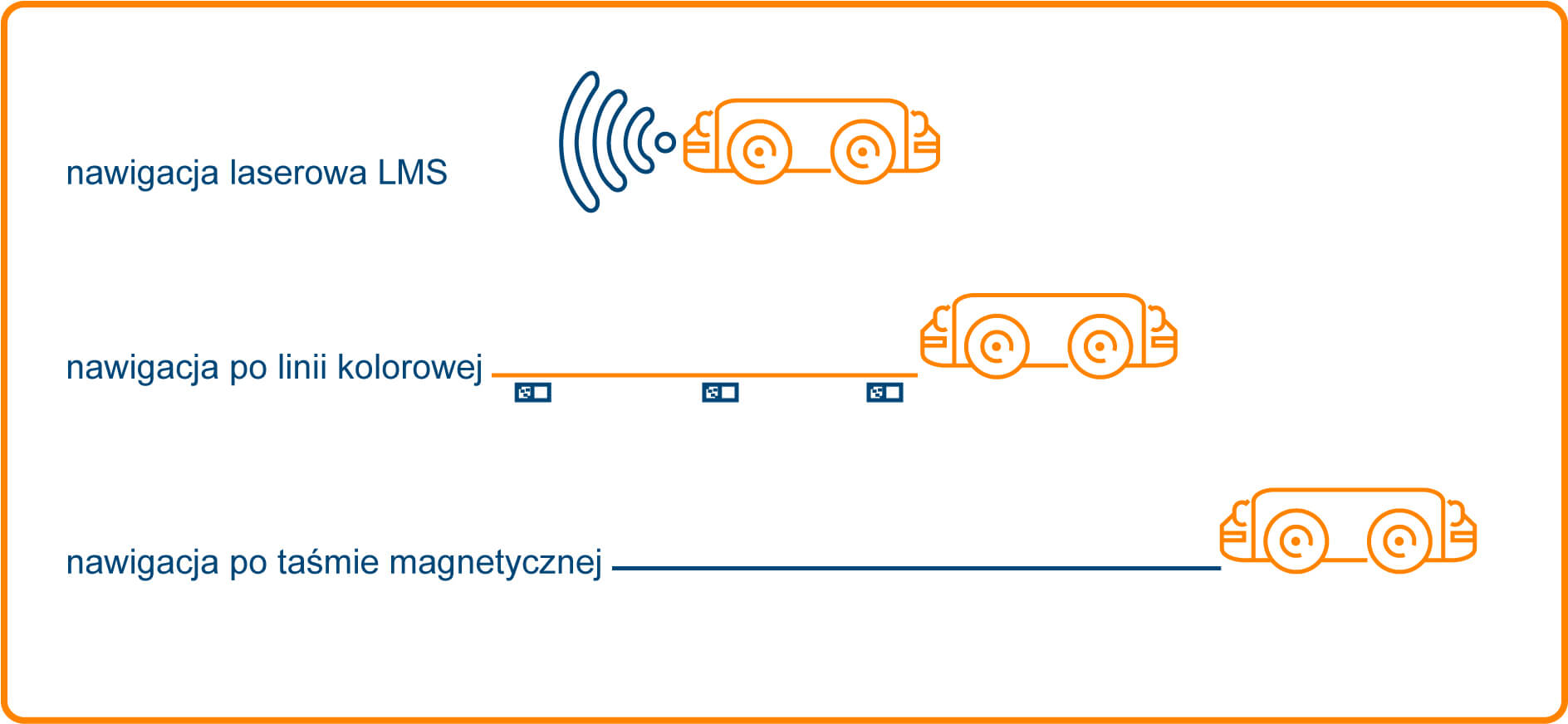

It should be started from the fact that there are several methods of robot navigation in space, each of which has its advantages and disadvantages, depending on which they are more or less popular.

In connection with the history of AGV robots, everyone will find ways to follow the induction, magnetic or color lines. The latter is still very popular, because it is a flexible method, quick to implement and with a good price-performance ratio. In addition to the line, the route is usually marked with QR codes or RFID tags informing the robot about stations and characteristic points.

However, the most interesting thing is surely laser navigation , which ensures independence of the robot in space. The WObit company has developed its own LMS laser navigation system (Laser Mapping System) and its example will show you the principle of action.

The principle of laser navigation

In contrast to conventional methods, the LMS system does not need any additional components mounted in the environment (such as codes, reflectors, etc.). Natural objects are used for navigation, such as walls, machines, gates, etc., which are measured using a mobile robot's laser scanner. This information serves to create a co-ordinate system in which the AGV robot will move along the virtual line. This way of creating a map, unlike the SLAM (Simultaneous localization and mapping) system, in which the robot locates itself on the basis of previously acquired experience, ensures significantly higher predictability of activity and repetitive work. After creating the map, the robot will move deterministically over it, defeating the route in the same way, unless the environment conditions significantly change (eg changing the location of a large machine). Such a method of laser navigation works especially in factories, where there is a lot of movement of various objects (eg fork-lift trucks) occurring along the robot's route, in particular compared to navigation with a colored / magnetic line that can be dirty or destroyed.

A mobile robot that uses the LMS navigation system is fast in implementation. In order to prepare a traffic route, a robot's initial travel is required, during which he scans the environment using laser scanners with the measurement function. The data is transferred to the software on the PC to generate the initial map, then after making the necessary correction it can be sent to the LMS system installed on the robot. After downloading the data to the software, under the supervision of a man, the map imprints and removes errors caused by slips or incorrect odometry*. The final stage of the map creation process is verification of navigation correctness, after which the robot is ready to work. It takes from a few to several hours depending on the route size and the surroundings. Positioning accuracy depends on environmental conditions and in the worst case is ± 1 cm.

* Odometry is a measure of measurement that deals with the measurement of distances. To measure the road, we use, among others information from encoders placed on robot wheels. They allow you to specify a change of the robot's position relative to the starting position over time.

Did you get interested in this article?

If you have any question contact our specialists.