Intralogistics involves the movement of materials and products within the production plant - from taking raw materials to storage, to the release of finished products.

The abbreviation 4.0 in the title refers to the concept of industrial revolutions. Its quintessence can be included in three words: digital, automated and connected.

In the beginning: why a revolution, not an evolution?

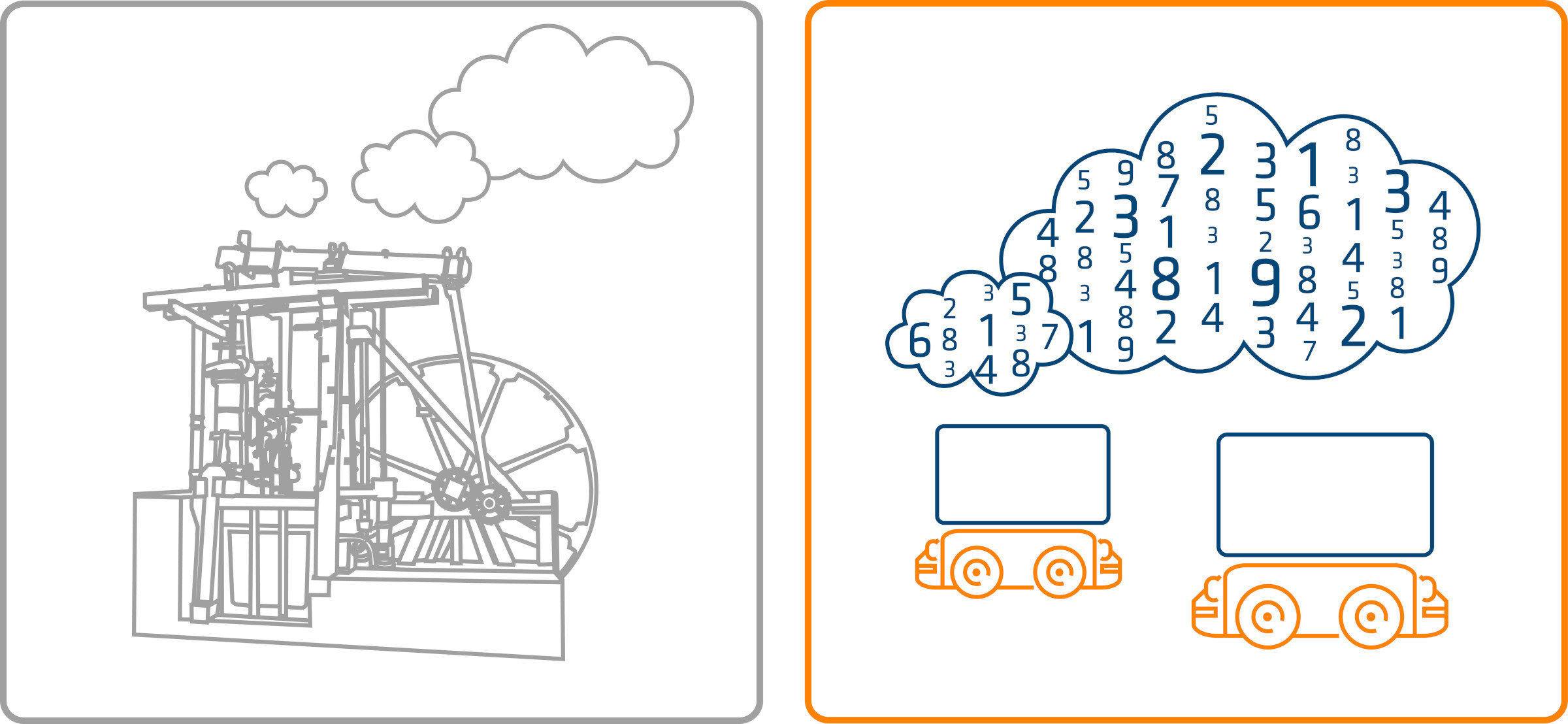

Revolutionary changes in the industry are the result of introducing transversal technical inventions that rapidly accelerate development as opposed to gradual changes. The first industrial revolution was related to the popularization of the steam engine and work mechanization, the second with the implementation of mass production techniques, the third with the introduction of electronic systems automating production processes. All these events increased the efficiency and effectiveness of enterprises.

In recent years, to ensure optimization of production companies, the industry will start introducing the latest IT technologies such as cloud computing, Big Data, Internet of Things (IIoT). These tools allow operations based on collected and processed information in real time. This digitalization and the combination of devices in constantly communicating networks are such a breakthrough that we can talk about the fourth industrial revolution.

The close integration of digital systems and physical processes is called cyberphysical systems. They are most often in the form of embedded systems, monitoring networks and control of physical processes that operate in the feedback loop. This is because data collected from the physical processes being carried out constitute the basis for controlling objects and process optimization.

Cyber-physical systems are used in computer-integrated manufacturing, where the key is the combination of existing IT (digital) systems for efficient management of automated physical processes. The result is the so-called smart factory, or an integrated future factory.

Where is intralogistics in all this?

Speaking about the implementation of the Industry 4.0 concept in the context of internal logistics processes, one should take into account the automation, digitization and connection mentioned at the beginning. This means the introduction of a process management IT system, network communication and automatic management as well as modern transport equipment such as autonomous mobile robots.

They move products to shipping or packaging areas, often very far away, which saves employees time. In terms of ergonomics, perform tasks that are too heavy for people, and can also work in hazardous or harmful zones.

Flexible and safe internal transport

Self-propelled transport trucks take up much less space, they have compact dimensions that allow them to move even on narrow paths. What is important, they can safely move in the same communication sequences as people. Therefore, it allows better use of the available workspace.

MOBOT® AGV autonomous robots are equipped with LMS laser navigation, thanks to which they do not require changes in the factory or warehouse space. Easily program them and implement them, and thanks to various adapters and trucks, you can easily change their functionality. The self-propelled vehicle transport system is also scalable. It means that the solution can be expanded according to needs and adapted to the development of the enterprise.

It is worth emphasizing that the robot management system can be integrated with the warehouse management system or material flow in the company. This will allow you to perform the tasks automatically and, above all, get a better control of the actual inventory. As a result (depending on the organization of production and inventory) it is possible to shorten the time of execution of orders and to produce personalized products on a mass scale.

As a result, you can get, among others reducing resources, saving time and improving the ergonomics of the work.

It is worth remembering that it is not enough to buy the device to achieve the mentioned results and the matter is implemented. Modernization of intralogistics processes should be preceded by an analysis of the processes and needs of a given enterprise. This will allow you to determine which solutions will be optimal and enable the implementation of strategic goals of the company.

Did you get interested in this article?

If you have any question contact our specialists.