Mobile robots help companies increase profits and meet customer requirements by optimizing internal transport processes. In this article, we present the key factors that indicate that mobile robots will work for your application.

1. Cargo transportation is the main task of employees

If your employees spend the lion's share of their time moving components and finished products within your warehouse and production, the mobile robot can help. Transporting parts from one place to another does not provide your company with value, it is an expense, and by automating the transport you can reduce production costs as well as increase efficiency.

While the robot carries loads, humans will be able to concentrate on tasks that require the use of their unique abilities and skills. At a time when it is not easy to find qualified people for your team, it is worth looking inside your organization and investing in the development of your employees.

If you're ready to take workers to more valuable tasks from pushing / pulling a cart and letting robots reduce operating costs, consider implementing Industry 4.0 technology in your company. Be sure to explain to your employees how robots will help them with their work without replacing them. This will greatly facilitate the effective implementation of technology in your company.

2. You want to limit the use of forklifts

Ensuring safety is an important issue in the areas of production and warehouse and is often a driver of change, influencing the decision to automate.

Self-propelled trucks are safer compared to forklifts requiring an operator. When a person is tired or sick, it is easy to distract him or cause a delay in action. Then it is not difficult to have an accident. This is confirmed by the research published on a>, according to which more than 90% of accidents at work are caused by inappropriate behavior of employees, while for the processing industry this percentage is over 50%. This applies especially to repetitive tasks in the production and warehouse space, such as transporting cargo from place to place - tasks for which they were created MOBOT® mobile robots . They meet stringent safety standards , thanks to which they can work safely among people. About safety standards read more here.

By replacing employees with unmanned trucks , the likelihood of their mistakes is also reduced. In the case of AMR robots ( Autonomous Mobile Robots ), the reaction time is supervised by the safety system, which when an obstacle is detected, it starts braking the robot within milliseconds, guaranteeing its absolute stop in a specific zone.

Safety scanners reliably detect obstacles and ensure that the robot reacts appropriately.

3. You're running out of space

Your company is developing and you want to introduce a new technological line or expand the existing one. You use traditional stationary feeders , fixed in specific places in the production hall, which provide you with a very efficient transport of loads. However, they require precise planning, a list of points connecting individual stages of the process, foreseeing communication routes and ways of connecting feeders. Moreover, in the case of transverse routes, it becomes necessary to use expensive solutions, e.g. elevators.

It is also not easy or cheap to rearrange the components of an existing system in order to modernize it to current and future needs. At some point, the only choice is to expand the production or warehouse hall. Are you sure the only one?

Instead of these elevators, you can use AGV robots , including autonomous AMR robots , such as MOBOT® enabling the continuation of automatic transport. Mobile robots mają zoptymalizowaną pod kątem wymiarów konstrukcję, która pozwala im na sprawne i bezpieczne przemieszczanie się w standardowych ciągach komunikacyjnych. Roboty AMR umożliwiają też realizację dostaw bezpośrednio do gniazd produkcyjnych w ilościach dostosowanych do bieżącego zapotrzebowania na materiały.

4. You often change the manufactured products or personalize them for your customers

Until now, your factory has been dominated by belt conveyors or monorail systems that ensure fast load handling. Their implementation was a large and costly investment that consumed a lot of time and resources, but ensured high efficiency. Of course, the maintenance services constantly monitored the processes to ensure the continuity of logistics processes, as even a minor failure or the need for retooling caused costly downtime in production.

However, the products you supply began to have a shorter and shorter life cycle, limited to even a few months, after which it was necessary to changeover to new products. In order to meet the expectations of its customers looking for unique and more personal items, the idea for personalization of products appeared. However, how to quickly adjust the production of a product without costly modernization?

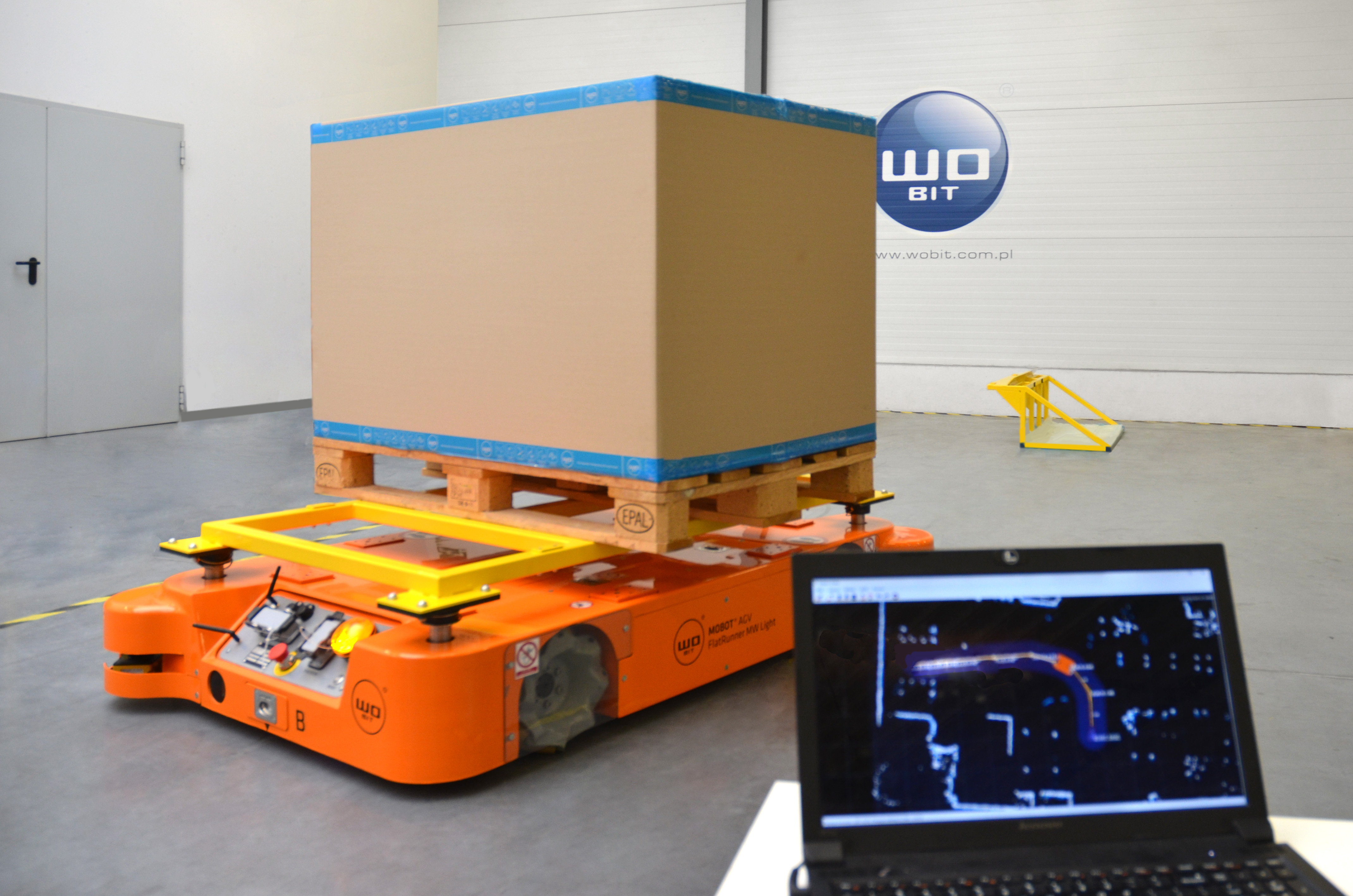

This is where AMR robots such as MOBOT® mobile robots are the answer characterized by high flexibility. It is based on easy adaptation to existing processes without the necessity to introduce significant and costly changes in the factory space. If the object has a flat, even floor, the robot navigated using autonomous LMS navigation creates a map of the area, allowing for efficient and safe movement in the environment without additional markers.

Autonomous LMS navigation provides autonomous operation of MOBOT® mobile robots

Then, the points between which the robot is to move are determined, as well as the place where its charging station is located. You can easily change the pick-up and drop-off points of transported goods when the need arises. What's more, it is easy to adapt the robot to the transport of completely different products by quickly replacing the extension module or the trolley, of course, provided that the weight of the product does not change drastically, exceeding the permissible load of the robot.

Therefore, when you need to frequently modify logistics processes and reliably, regularly provide transport of details between the stages of the production process or between the production hall and the warehouse, consider the use of AMR robots.

5. You need a device that is easy to deploy and configure

Many automation solutions after implementation bring many benefits, but the process of their commissioning and configuration is often time-consuming and increases the final cost of the investment. If you have encountered it many times and you are looking for an intuitive, affordable and quick device to configure , it's time to get to know the new solution in the MOBOT® robot family - MOBOT® TRANSPORTER U1.

MOBOT® TRANSPORTER U1 was created precisely in response to the need for an inexpensive, easy-to-use device that you can implement yourself. The configuration has been simplified into a simple tutorial, with which you will configure the parameters of your robot step by step. There is no need for expensive and long-term installation of the device, carried out by a highly specialized integrator.

Due to the fast, self-implementation and low cost of the robot MOBOT® TRANSPORTER U1 , you can get a very quick return on investment , even when replacing the work of only one person in single-shift operation. This means that in almost every company, organization, institution or facility it pays to introduce robots MOBOT® TRANSPORTER U1 for transport tasks.

Are you interested in the article? There are factors in your company that indicate the need for optimization with the use of mobile robots? Do you want to learn more about the possibilities offered by MOBOT® robots? Contact our advisor and get your questions answered .

Did you get interested in this article?

If you have any question contact our specialists.